Hydraulic systems are widely used in various industries due to their efficiency and reliability. From heavy machinery to simple tools, hydraulic systems have become a crucial part of many operations. However, the performance of these systems can be compromised if the appropriate hydraulic products are not chosen or if they are not maintained properly.

In this article, we will discuss the essential hydraulics products that you need for optimal efficiency. We will cover the heart of your system: hydraulic pumps, how to choose the right valves for your needs, and why filters and hoses matter. Additionally, we will provide maintenance tips to ensure maximum efficiency from your hydraulic system. By understanding these critical components and their importance in maintaining an efficient hydraulic system, you can improve your operations’ productivity while reducing downtime and maintenance costs.

Hydraulic Pumps: The Heart of Your System

Table of Contents

- Hydraulic Pumps: The Heart of Your System

- Choosing the Right Valves for Your Needs

- Filters and Hoses: Why They Matter

- Maintenance Tips for Maximum Efficiency

- Frequently Asked Questions

- 1. What are the common causes of hydraulic pump failure?

- 2. How do you determine the appropriate valve size for your hydraulic system?

- 3. Can you mix and match different brands of hydraulic hoses and filters?

- 4. What are the consequences of not performing regular maintenance on your hydraulic system?

- 5. Is it necessary to use specialized hydraulic fluids, or can you use other types of oil?

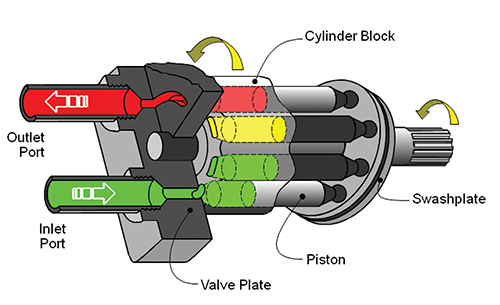

The hydraulic pump serves as the central component of the system, functioning as its heart and providing a critical source of power to enable the smooth operation of machinery. Hydraulic pumps come in different types, such as gear pumps, vane pumps, and piston pumps. Gear pumps are known for their simplicity and low cost, while vane pumps offer higher performance than gear pumps due to their greater efficiency in handling viscous fluids. Piston pumps are more complex but provide better durability and control over flow rates.

To ensure that your hydraulic pump operates optimally, regular maintenance is necessary. This includes checking for leaks or damage to seals, filters, and valves. It is also essential to monitor fluid levels regularly since inadequate fluid can cause cavitation inside the pump leading to failure or damage of internal components. In case of any malfunctioning or failure of the pump, troubleshooting tips include checking for damaged parts like worn-out bearings or clogged filters that may affect its performance. Proper maintenance procedures not only prolong the lifespan of your hydraulic pump but also helps prevent costly repairs or replacements down the line.

Choosing the Right Valves for Your Needs

Selecting appropriate valves like humphrey valve is essential for achieving maximum productivity and ensuring the smooth operation of your hydraulic system. Valve selection criteria must be considered when choosing the right valve for your needs. These include flow rate, pressure rating, operating temperature range, compatibility with fluid types, and application-specific requirements such as noise reduction or space limitations. Common valve types and their uses are also important to understand when making a decision.

The most common types of valves used in hydraulic systems are ball valves, check valves, relief valves, directional control valves, and flow control valves. Ball valves are ideal for on/off applications in high-pressure environments. Check valves prevent reverse flow in the system while relief valves protect against overpressure situations. Directional control valves manage the direction of fluid flow within the system while flow control valves regulate the fluid’s speed or volume through a specific point in the system. Selecting the right type of valve will depend on its intended use within your hydraulic system and how it can meet all necessary criteria for optimal efficiency.

Filters and Hoses: Why They Matter

Filters and hoses are indispensable components of any hydraulic system, as they play a vital role in ensuring the purity and integrity of the fluid medium that powers the machinery. The importance of cleanliness cannot be overstated when it comes to hydraulic systems. Contamination can cause significant damage to components such as valves, pumps, and cylinders, leading to costly repairs or replacements. Filters help prevent contamination by trapping particles such as dirt, debris, and metal shavings that may enter the system through wear or other sources. They also help maintain consistent pressure levels by preventing blockages caused by contaminants.

The longevity of hoses is another crucial factor in maintaining optimal efficiency in hydraulic systems. Hoses transfer fluid under high pressure from one component to another, making them subject to extreme stress over time. As hoses degrade or fail due to age or damage, leaks can occur that compromise the system’s performance and increase the risk of damage or injury. Regular inspection and replacement of hoses are essential for avoiding these problems. Choosing high-quality hoses made from durable materials and rated for specific applications is also critical for minimizing downtime and maximizing efficiency in hydraulic systems.

Maintenance Tips for Maximum Efficiency

Maintenance practices are essential for sustaining the performance and reliability of hydraulic systems. Prevention measures such as regular inspections, testing, and filter replacements can help prevent system failures or breakdowns that may lead to expensive repairs or replacements. Timely troubleshooting techniques also play a significant role in maintaining optimal efficiency. Identifying small issues before they escalate into bigger problems is an effective way to minimize downtime and maximize productivity.

It’s recommended that regular inspection intervals be established based on factors such as machine usage, environmental conditions, and manufacturer recommendations. During these inspections, technicians should check for signs of wear and tear on hoses, fittings, seals, and filters. Replacing worn-out hoses and filters with high-quality alternatives will help maintain maximum efficiency by ensuring that the system operates at peak performance levels. It’s also important to use compatible parts when replacing components to avoid incompatibility issues which could result in reduced efficiency or even damage to the entire system.

Frequently Asked Questions

1. What are the common causes of hydraulic pump failure?

Hydraulic pump failure can be caused by a variety of factors, ranging from simple issues such as low fluid levels and dirty filters to more complex problems like worn-out bearings and broken shafts. One effective way to prevent pump failure is through regular preventative maintenance, which involves conducting periodic inspections and replacing parts that have reached the end of their useful life.

Troubleshooting techniques can also be used to identify potential issues before they lead to pump failure. This includes monitoring pressure levels, checking for leaks, and listening for unusual noises during operation. By taking a proactive approach toward identifying and addressing potential problems, hydraulic system operators can ensure that their pumps operate efficiently and reliably over the long term.

2. How do you determine the appropriate valve size for your hydraulic system?

Sizing considerations and valve selection criteria are crucial factors in determining the appropriate valve size for a hydraulic system. Various parameters such as flow rate, pressure drop, fluid viscosity, and temperature should be taken into account before making the final decision. The valve size should be chosen according to the maximum flow rate required by the system to ensure that it operates efficiently without experiencing any backpressure or cavitation issues.

Additionally, selecting a valve with an appropriate Cv value is also essential as it determines its ability to control flow effectively. Other factors such as space constraints, budget limitations, and compatibility with other components of the hydraulic system also need to be considered while selecting the right valve size for optimal performance.

3. Can you mix and match different brands of hydraulic hoses and filters?

Hydraulic fittings compatibility is essential for the proper functioning of a hydraulic system. Mixing and matching different brands of hydraulic hoses and filters can lead to incompatibility issues, which can result in leakage, pressure drops, or even system failure. Therefore, it is best practice to select hoses and filters from the same manufacturer or ensure that they are compatible with each other through rigorous testing.

Factors such as pressure rating, temperature range, chemical resistance, and hose construction should be considered when selecting hydraulic hoses and filters. Additionally, regular inspection and maintenance of the hydraulic system can help identify any potential compatibility issues early on before they cause significant damage.

4. What are the consequences of not performing regular maintenance on your hydraulic system?

Regular maintenance is crucial for the optimal performance and efficiency of hydraulic systems. Neglecting to conduct regular maintenance can have significant consequences on the system’s overall functionality, leading to decreased efficiency and increased downtime. The importance of maintenance cannot be overstated, as it ensures that all components are operating correctly and that any potential issues are caught before they become major problems.

A lack of proper maintenance can result in a build-up of contaminants, such as dirt and debris, which can clog filters and reduce oil flow. This can lead to excessive wear on components, resulting in premature failure or breakdowns. Inadequate lubrication due to dirty oil can also cause frictional losses that decrease efficiency over time. Ultimately, neglecting regular maintenance will impact the overall efficiency of your hydraulic system negatively.

5. Is it necessary to use specialized hydraulic fluids, or can you use other types of oil?

Image source: .designworldonline.com

The use of specialized hydraulic fluids is necessary for the optimal performance and longevity of a hydraulic system. Synthetic fluids, in particular, offer several benefits over conventional mineral-based oils. They have higher resistance to oxidation, which prevents the formation of sludge and varnish that can clog filters and reduce efficiency.

Additionally, they provide superior low-temperature performance, ensuring smooth operation even in cold environments. When selecting a hydraulic fluid, it is essential to consider its compatibility with different materials used in the system such as seals and hoses. Incompatible fluids can cause degradation or failure of these components leading to costly repairs. Therefore, using appropriate hydraulic fluids is crucial for the efficient and trouble-free operation of hydraulic systems.

Conclusion

Hydraulic systems are like the circulatory system of your machinery, with the hydraulic pump being the heart. Valves act as arteries, and filters and hoses function as veins, all working together to ensure optimal efficiency. Just like maintaining a healthy heart is crucial for overall health, selecting appropriate pumps and valves for your hydraulic system is crucial for its performance.

Choosing the right values can be likened to choosing a healthy lifestyle. A balanced diet of different nutrients provides our bodies with what they need to function properly. Similarly, selecting valves that match your specific needs will help keep your hydraulic system running smoothly. Filters and hoses act as cleansing agents in our allegory; just as veins carry impure blood toward the heart to be cleansed by the lungs or kidneys, so do filters remove contaminants from hydraulic oil before it reaches the pump.

In conclusion, maintaining efficient hydraulic systems requires attention to detail when selecting components such as pumps and valves while ensuring clean oil flow through regular maintenance of filters and hoses. Using this allegory can help emphasize how essential each component is in keeping your machinery operating at peak performance. So take care of your “circulatory” system by selecting quality hydraulics products today!

- How To Create A Safe And Comfortable Home Environment For In-Home Care In Boca Raton? - July 16, 2024

- 10 Trendy Black Nail Ideas To Elevate Your Nail Game - May 6, 2024

- Getting A Free Divorce In Virginia? Here’s What To Expect - April 24, 2024

No Comments